Zenotech is a high-tech simulation specialist, developing high performance computing for the aerospace, automotive, civil and renewable energy sectors. The company delivers simulation at scale for organisations of all sizes needing faster, more accurate and cost effective simulation.

Zenotech is leading an Aerospace Technology Institute (ATI) funded project called Hyperflux ++; a collaboration with Bombardier, CFMS and the Aircraft Research Association. The project aims to further develop capability for specific challenges in the aerodynamic modelling of undercarriages and nacelles. Complex test cases of up to 30,000 surfaces at one time, are to be modelled by the software in the project.

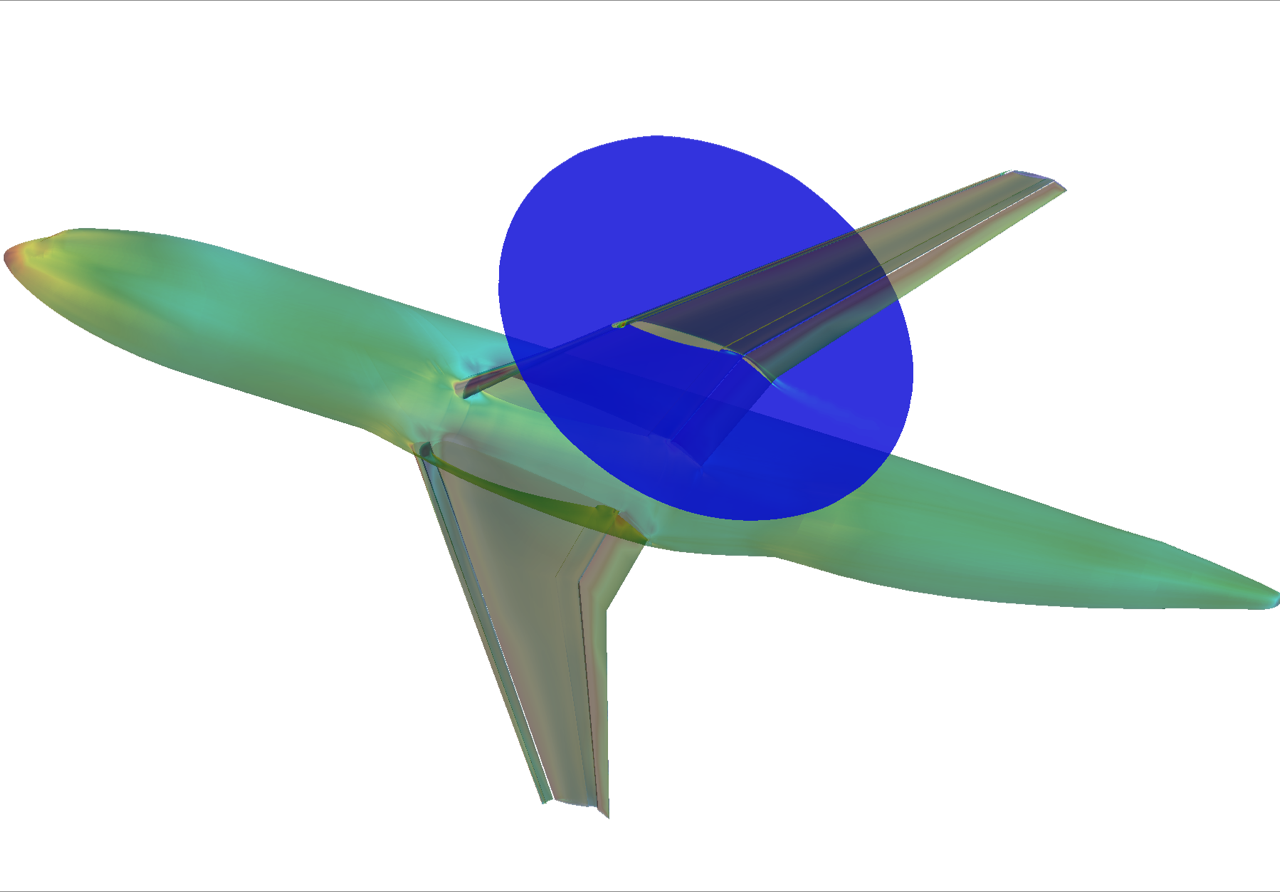

Hyperflux ++ builds on a previous successful Innovate UK funded project, Hyperflux, which looked at developing next generation Computational Fluid Dynamics (CFD) technology for the civil, automotive, renewable and aerospace sectors, using the cutting-edge high order flux reconstruction technique designed at the Imperial College London. Hyperflux created a new software tool, named zCFD, underpinned by expertise within the UK, which is freely available for academic research and for any individuals to use on a single device.

David Standingford, Company Director at Zenotech and project lead, said:

“These technologies can take time to develop, but introducing the right partners with the right expertise is critical to getting these products to the market ahead of our competitors.

“The ATI project has been a huge opportunity for the SME participants as it has given us the chance to work with an aerospace Prime that we were previously not visible to, as well as offset the costs of the project for all involved.

“The ATI and Innovate UK are extremely important mechanisms; the collaborative research projects, with SMEs as leads, funding directed by Primes, and an agreed timescale, ensures the usual barriers to entering a new project are removed. They understand that the adoption of new technology, especially for Primes, can take a long time to be approved and integrated, so the timescales reflect this”.

More accurate simulations, with accelerated run times have put this technology at the fore of the sector. It is estimated that aerodynamic analysis time will be accelerated by at least 10 times for the same fixed cost, significantly increasing design productivity and throughput. In addition, the tool has the potential to be applied to the design of new aircraft architectures.

A key aim of the ATI’s strategy is for its projects to explore, where possible, a range of important cross-cutting topics transforming technology and manufacturing more broadly. A major benefit of this project is technology spillover, as the design tools are used in a range of sectors, including civil engineering, renewable energy and automotive engineering. The technology outputs have already attracted the attention of a number of potential new customers.

For maximum accessibility, the capability is available to all UK organisations via cloud access through the EPIC high performance computing (HPC) portal, allowing users to securely access the virtually unlimited data in the cheapest way possible.