Airbus has today achieved the first flight of its new A320neo (new engine option) single aisle airliner. The current A320ceo is the ‘workhorse’ of the Airbus fleet, and the new updated version is set to continue this success with over 3,200 orders – achieving its 3,000 order milestone at this years Farnborough International Air show.

The aircraft is set to enter service in Q4 2015 – alongside continuing production of the A320ceo – with final assembly lines eventually transitioning into the full ‘neo’ platform production as orders for the current generation A320 are fulfilled. This transition will be important for the UK’s aerospace industry supply chain as single aisle delivery rates are set to increase significantly over the next few years.

UK industry has significant involvement in the A320neo project – the East Factory at Airbus’ Broughton facility will conduct final assembly of the wings of the A320neo, supporting 2,500 jobs at Airbus and 7,500 throughout the wider Airbus supply chain in the UK.

The efficiency savings which underpin the order success of the A320neo derive from both the new engine and also, the new winglets – which were designed in Filton, Bristol. These technology improvements together are set to deliver a 15-20% fuel efficiency saving on the current A320 aircraft. The new engine is also significantly larger than the current A320ceo – 81” rather than 68” in fan diameter – meaning that although the airframe has 95% commonality, the wing structure has had to be developed to ensure it is capable of supporting the new engine effectively. Strong UK knowledge and expertise in wing technology & development (one of the most expensive areas of design on any aircraft) is therefore vital.

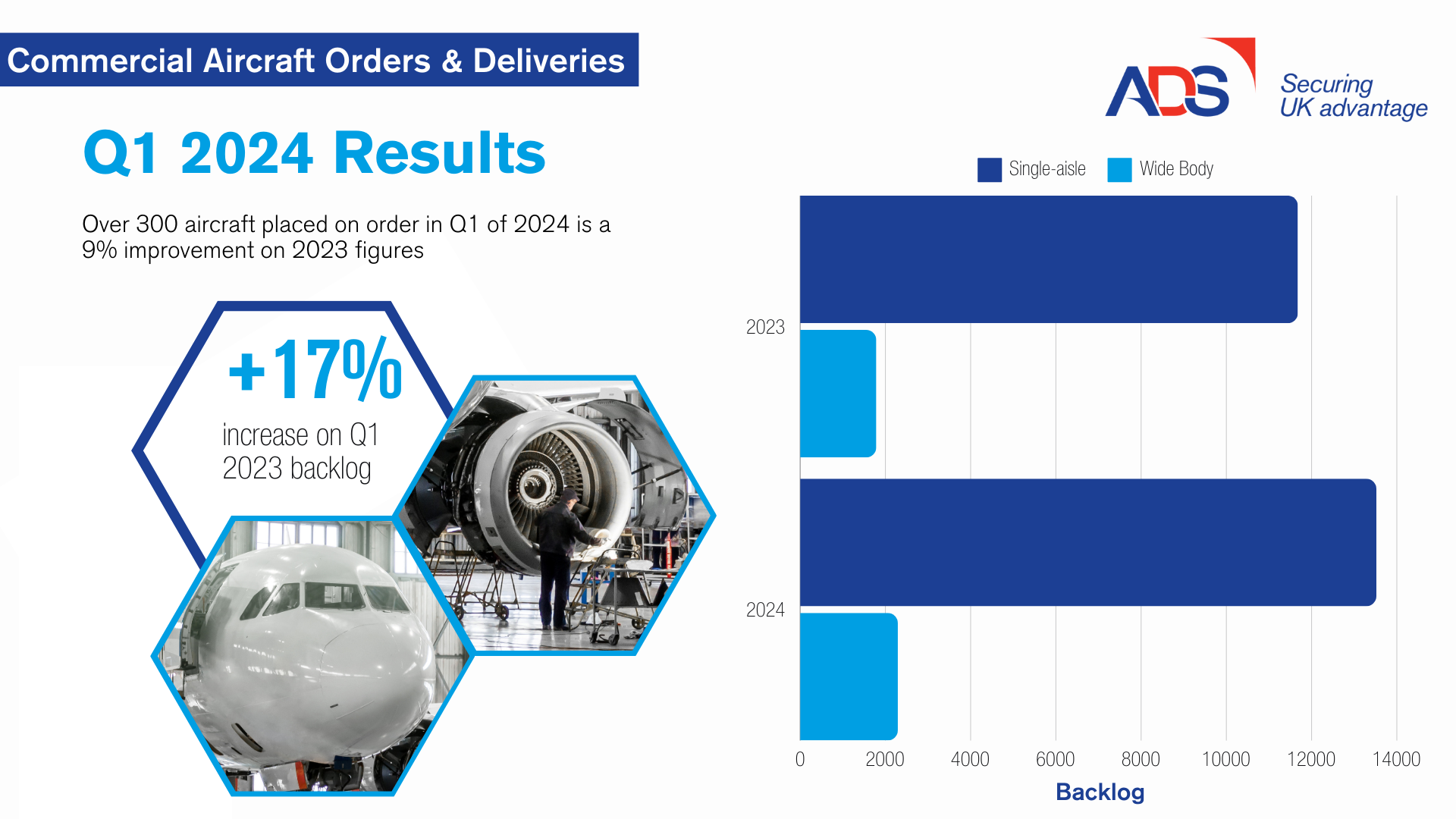

With over 9,000 single aisle aircraft in the current backlog and forecasts for over 22,000 by 2033, the UK’s relationship with and continued work on the A320neo as it begins operations and delivery, will be vitally important to sustaining our strong aerospace market position.